Over the past 22 years, Michael Reynolds at Leading Edge Power has made thousands of stators, an integral part of small wind turbines, all hand made in the UK to a rigorous quality standard. To celebrate this achievement, Fiona Reynolds, his niece created a special Stator cake!.

The stator is an important part of the wind turbine - it contains coils of wire which will have voltage induced in them as the magnets pass over them. Michael has now passed the baton on stator production to Fiona Reynolds, Office and Production Manager at Leading Edge.

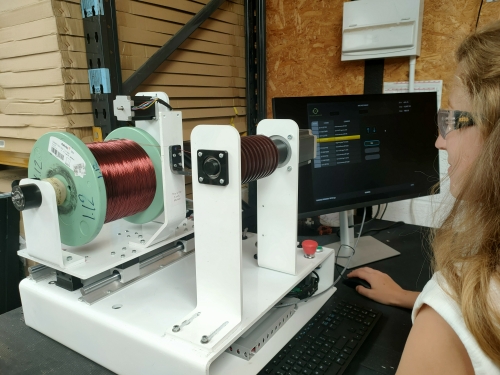

A computer controlled, semi-automatic winding machine developed by Greg Reynolds, electrical engineering entrepreneur who is also Michaelís son, is now in production. The machine enables the company to produce the higher volumes of stators required as the market for renewable energy continues to grow.

Unlike other wind turbine manufacturers, the stators continue to be made in the UK and to the motor axial flux design.

Michaelís focus is now on R&D and together with Thomas Hunt, Engineering and Sales Manager, he is developing the next generation of wind turbines which will be released in the new year. Innovation around stator design will increase power production, a benefit of managing stator production in-house. Importantly the wind turbines must still be able to withstand the storm force winds that destroy other traditionally designed wind turbines.

The Leading Edge LE-300 wind turbine has a 22-year heritage as it was originally developed by Michael and Dave Samuel when the company Samray was established in 2000. Nine years later, the intellectual property was purchased by Neil Kerr and Leading Edge Turbines was formed with the Wren renamed the LE-300, so called because its power output reaches 300W at 18m/s

The Leading Edge wind turbine range now encompasses the vertical wind turbines, the LE-v50 and LE-v150 and their Extreme versions that can withstand the harshest of environments. Our wind turbines continue to form an integral part of the off-grid power systems we supply and differentiate us from others in the off-grid space.

Tell us about your project

Our Off-grid experts will come back with recommendations